Category

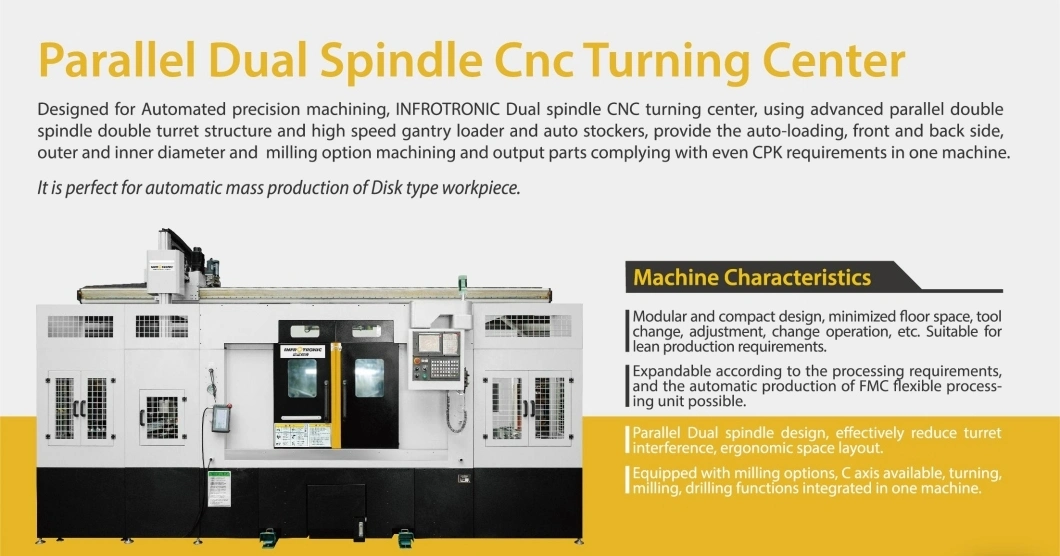

Parallel Double Spindle CNC Lathe Turning Center of TT20

Company Profile Zhejiang Infrotronic Intelligent Machinery Technology Co.,Ltd. is a joint venture of Jingxing Co.,Ltd. (

Basic Info.

| Model NO. | TT20 |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | ISO 9001 |

| Condition | New |

| Specification | 2900x2150x1850mm |

| Trademark | INFROTRONIC |

| Origin | Zhejiang Pinghu |

Product Description

| Item | Unit | TT20 | |

| Range | Max Swing | mm | Φ320 |

| Max Machining Diameter | mm | Φ280 | |

| Max Machining Length | mm | 110 | |

| The X/Z axis Range | mm | 160/220 | |

| X/Z axis Fast Feed | m/min | 30/30 | |

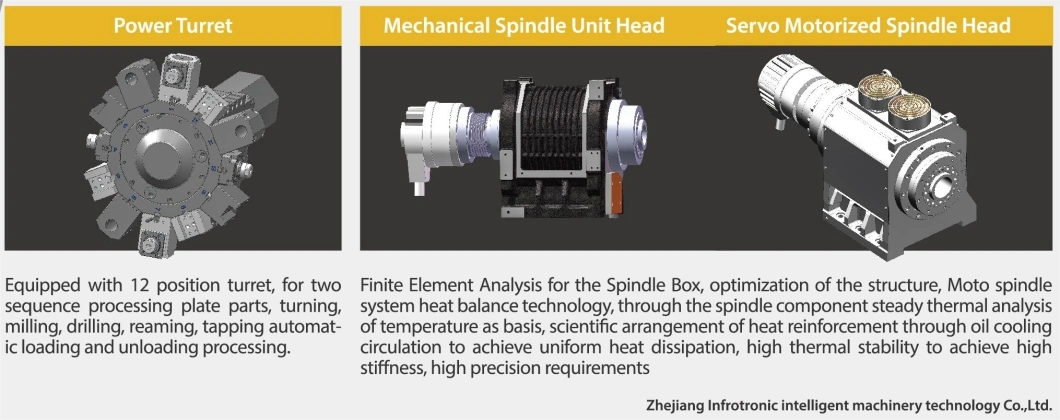

| Main spindle | Spindle Size | - | JIS A2-6 |

| Max Spindle Speed | rpm | 4000 | |

| Main Motor Power | kW | 11(x2) | |

| Main Spindle Through Hole | mm | Φ63 | |

| Max Bar Machining Diameter | mm | Φ52 | |

| X/Z Rotation | X/Z Rotation | rpm | 3000 |

| Type of Tool Holder | Turret | - | 12 Position Turret |

| Tool Holder | mm | 25x25 | |

| Boring Bar | mm | Ø40 | |

| Coolant Tank Volume | L | 200 | |

| Dimension(L x W x H) | mm | 2900x2150x1850 | |

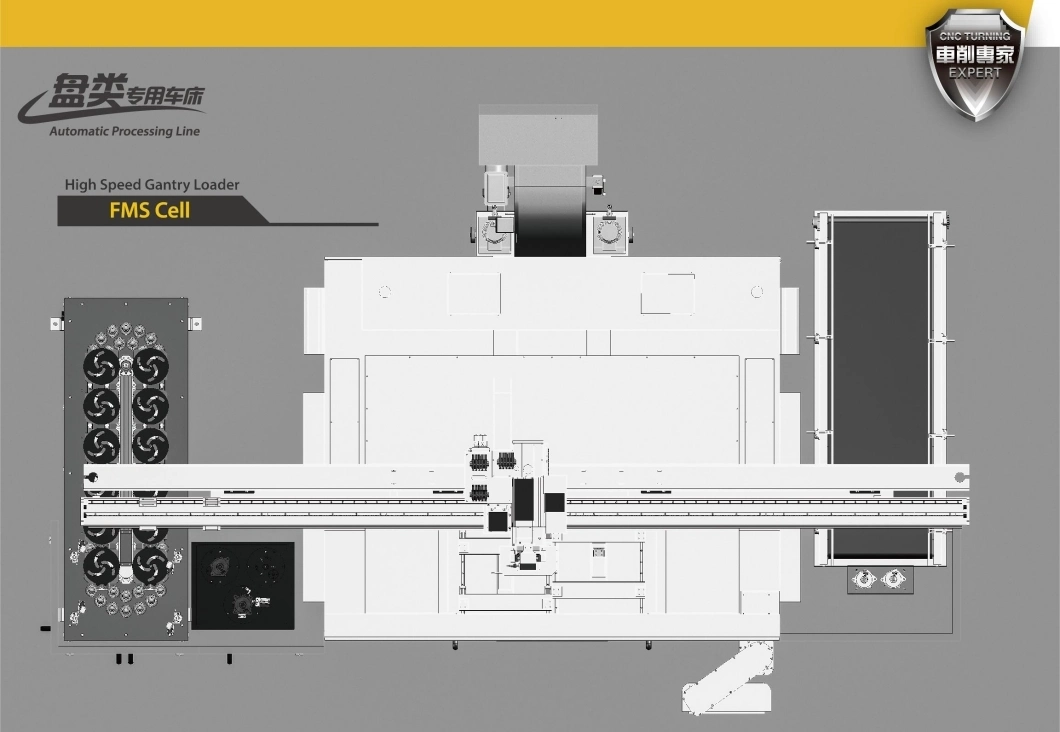

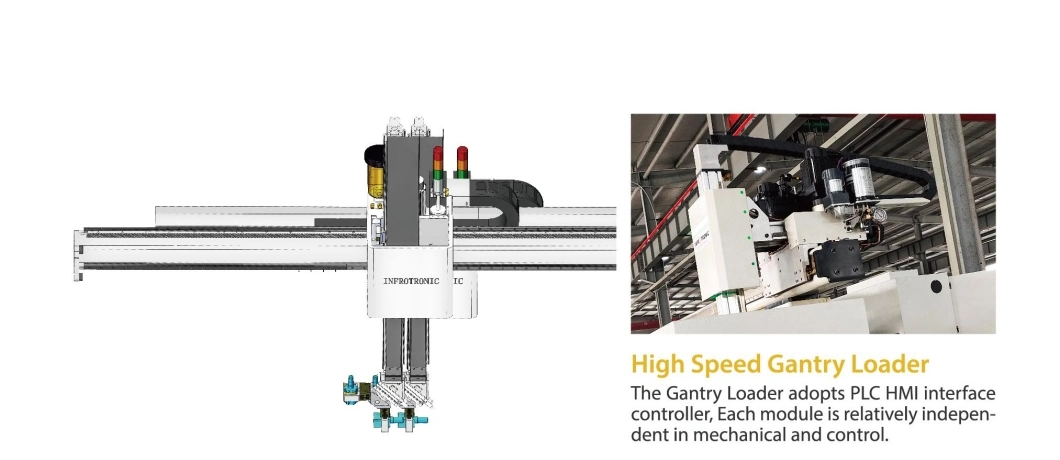

| Three Axes Gantry Robot | |

| Item | Parameter |

| Z-axis Material(beam) | Structural Steel |

| Z-axis Drive Mode | Pinion and Rack |

| Maximum Z-axis Moving Speed | 180(m/min) |

| Z-axis Drive Mode | Servo Drive |

| Y-axis Material(vertical Arm) | Aluminium |

| Y-axis Drive Mode | Pinion and Rack |

| Maximum Y-axis Moving Speed | 150(m/min) |

| Y-axis Drive Mode | Servo Drive |

| X-axis Material | Aluminium/Structural Steel |

| X-axis Drive Mode | Pinion and Rack |

| Maximum X-axis Moving Speed | 60(m/min) |

| X-axis Drive Mode | Servo Drive |

| Position Accuracy | ±0.05(mm) |

| High speed servo window | Cylinder Drive |

Note:

| |

Zhejiang Infrotronic Intelligent Machinery Technology Co.,Ltd. is a joint venture of Jingxing Co.,Ltd. (Joint-stock code: 002067), with a registered capital of 30 million yuan. The company is located in Jiaxing, Zhejiang, 60km from Shanghai. Covering an area of 30000 square meters and a construction area of 20000 square meters.

Infrotronic Intelligent is committed to building a world-class intelligent and digital factory that meets the industrial 4.0 standard for leading enterprises in various industries in China.

Infrotronic Intelligent is a state-level high-tech enterprise that has passed ISO9001 system certification and won honorary titles such as Zhejiang Provincial R&D Center, Jiaxing Municipal Technology Center and Jiaxing Pioneering and Innovative Talent Enterprise. Infrotronic Intelligent is the drafting member unit of the national standard for industrial robots and also the drafting unit of the national standard for metal cutting lathes. And has many invention patents and software copyright.

Akihito has an international core technology team, bringing in Japanese industrial intelligent technology experts and core technology members from well-known Japanese robot companies. Infrotronic Intelligent has all-round technical capabilities in software, intelligent control, electricity, robots, big data, industrial cloud technology, machinery and precision manufacturing.

At present, the company has 50 technicians, including 3 Japanese chief engineers and 10 senior engineers. The company has established long-term cooperative relations with Japan's ALMAC Automation Co.,Ltd. and the Robot Research Institute of Shanghai Jiaotong University.

The companys leading products mainly include the design and implementation of automatic processing units, gantry robots, precision lathes, automatic production lines for industrial robots and intelligent factories.

Akihito owns Japan OKUMA horizontal machining center, Japan MAZAK vertical machining center, imported large gantry machining center, precision internal and external grinding machine, large gantry milling machine and other large-scale production equipment. the testing equipment includes imported three-coordinate measuring instrument, high-precision laser interferometer, metallographic analyzer and other advanced testing equipment.

The products of Zhejiang Infrotronic intelligent machinery technology Co.,Ltd. have been widely used in home appliances, Crankshaftes, precision bearings, gears, automobile transmission axises, brakes, automobile fasteners, wheel hubs, air conditioning compressors, paper making, tobacco and other industries, and have been successfully applied in internationally renowned companies such as SKF of Sweden, SDS of Shanghai, helbice of Germany, ebech of Germany, Shanghai GM, jingxing paper and so on.

Infrotronic Intelligent will continue to innovate, introduce advanced Japanese technology, and continue to strive for Chinese enterprises to build industrial 4.0 standard intelligent factories and realize the ambitious dream of Made in China 2025.

Certification certificate

Provincial High tech Enterprise Research and Development Center

PRODUCTION SITE